by Kazu

The kind of rice crop to make sake is different from the ones for normal meal. They must be polished up to cut off their fat and protein to make high-quality Japanese sake. Approximately 70% of each rice crop should be taken off by polishing machine little by little to avoid heating up and changing the quality of the rice crops.

The fat and protein of the rice lead to bitterness and distastefulness.

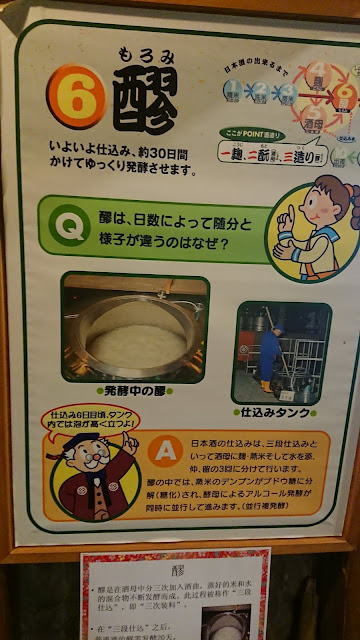

Steamed rice and clear water are put in the tank made of stainless steel nowadays but wooden tank had been used before.

It takes 30 days to make unrefined Japanese in the tank. Too fast fermentation is dangerous to make quality Japanese sake, so the temperature is completely controlled in the room.

Sake brewing masters stir the unrefined sake with the long stirring rod sometimes. Sake brewing had been done only in winter because controlling temperature was impossible in other season.When wooden tanks were used for fermentation in winter, snow was used to cool down the tank and to avoid too fast fermentation.But now that temperature control is easier than before, sake brewing is being done all the year round.

But now that temperature control is easier than before, sake brewing is being done all the year round. We can savor the quality Japanese sake fresh from the tank all the year round. Different from whisky, it doesn't have to be laid down in the wooden warehouse. Freshness is crucial and keeping the appropriate temperature is crucial for our happiness to savor quality sake.

No comments:

Post a Comment